Bag Sealer Basics

Bag sealer concerns are not a common topic. Most people don’t put too much thought into what they use to seal their bags. You see many incarnations of bag sealer in the market today. You will see a plastic thermal lock, and then the after-seal is with a ziplock. For example tortillas.

You see bag sealers in the form of cellophane wrap around a loaf of bread, followed by a polybag and over that. Finally, there is a plastic clip as your after-closure. It is cumbersome to deal with that cellophane inner bag with bread. Especially as you get down towards the bottom of the loaf, it tends to get in the way.

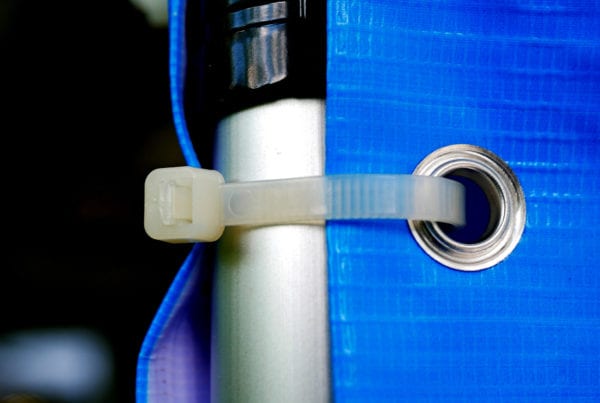

The plastic clips that you see in the market today do not provide an airtight closure after you open that bag. This might not lend very well to the lifespan of that bread. Also, a twist tie lets minimal air in, and oxygen is the enemy of food freshness. We take pride in providing machines that put a nice, solid, clean tie onto the bag. Most people desire to keep their bread fresher longer. They that by providing a nice solid twist with a metal twist tie.

Sealer Types

There are definitely lots of different bag sealer types. In some vacuum-seal applications, you will see the air removed from the bag, and then it’s sealed. Cellophane, a thermal seal around a bread bag – that’s a hermetic seal as well the vacuum bag. With the tortilla industry, you will see where you have a thermal seal, and then it’s got a micro perforation. That way, it’s easy to remove that seal and also provides elements of tamper evidence. Tamper evidence is desirable for a lot of companies for obvious reasons. given that with food on a shelf, you don’t want anybody getting their hands in the bag.

Some different bag sealer alternatives. What you see on the market shelves today with tortillas starts with the thermal seal. After that, the micro-perforation, and then the ziplock for re-closure. There are some issues with that. The resealability of it may or may not be there. Also, these bags can be difficult to find the track and zip it down. And if it stays open in your fridge, it’s not going to last as long as you would like it to. It gets a little cumbersome and frustrating to try and re-close that bag sealer up. With the plastic clip, you have some issues with oxygen getting in the bag and shortening the life of the food.

Twist Ties for Sealing

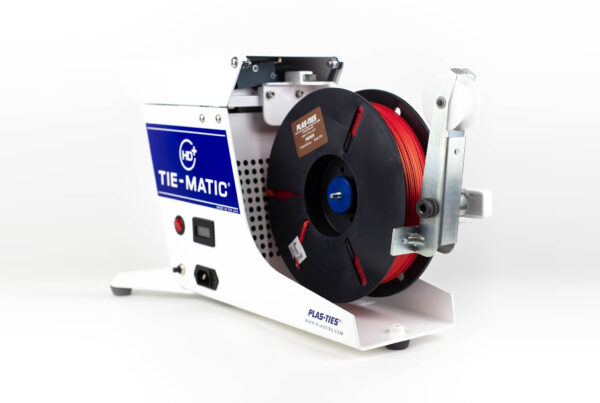

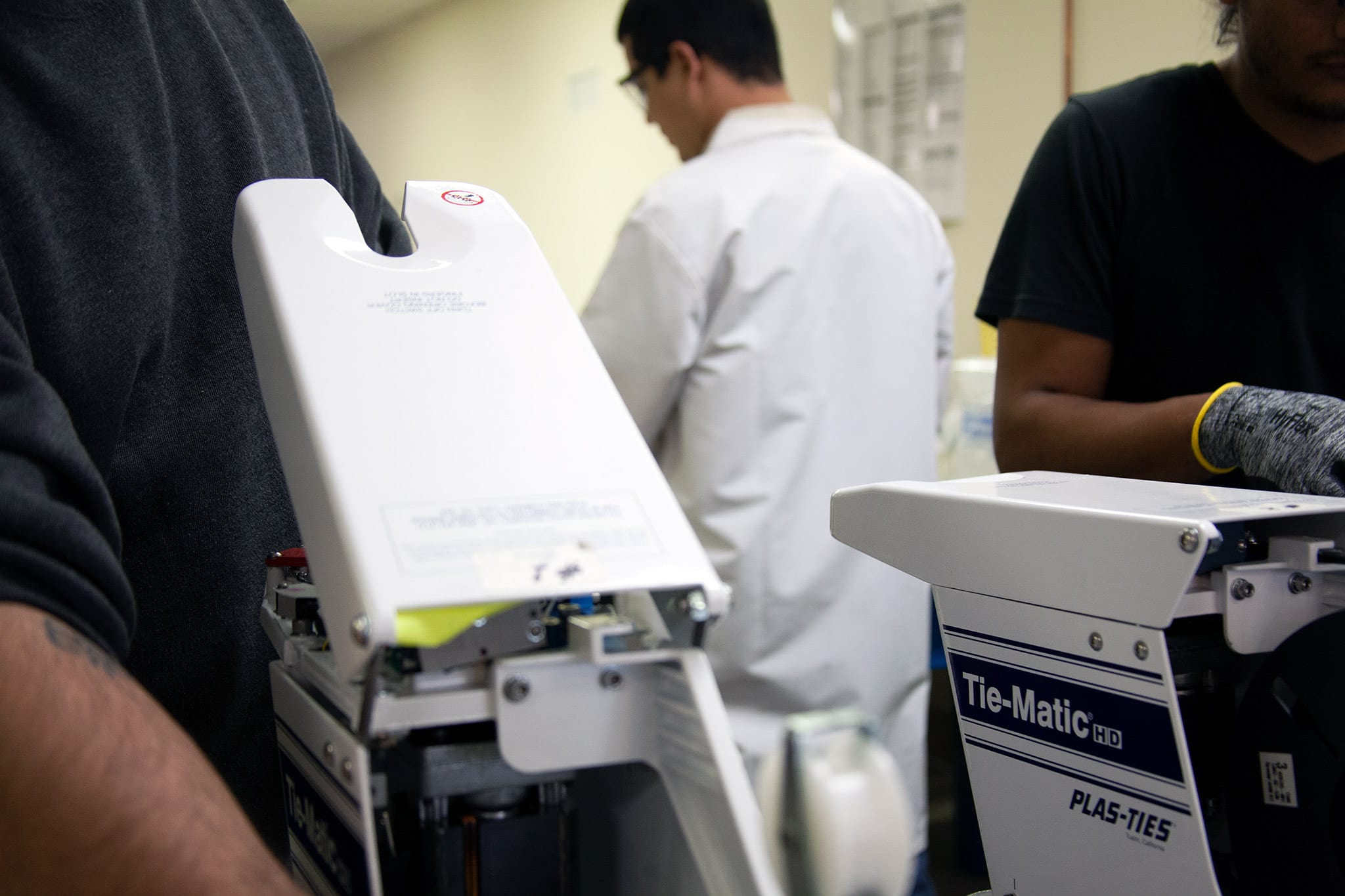

A great alternative is the twist tie. Plas-Ties does a great job to meet the needs of customer packaging requirements. That may involve printing a batch code or a lot code to the twist tie, and we do that now. We have products that are available that print on, real-time, with batch codes and lot codes. The bakeries or tortillerias can hold accountability for the products on the shelves. If there are any issues with bag sealers, their due diligence provides the customer with information.

It’s the customer-preferred application once the product is open. People love to use twist ties versus the plastic clip. It’s the preferred application. And, now, also we have technology that can apply an all-plastic bag sealer tie. As customers scale up, they tend to have more volume. Their loaves of bread or tortillas are going into palletized large batch goods. They run them through metal detectors for compliance with the various authorities. The plastic tie definitely serves both needs when passing through metal detection. They get to have the preferred closure, which is the twist tie. And they get to have the ability to metal detect through large batch operations.