Wire Ties Basics

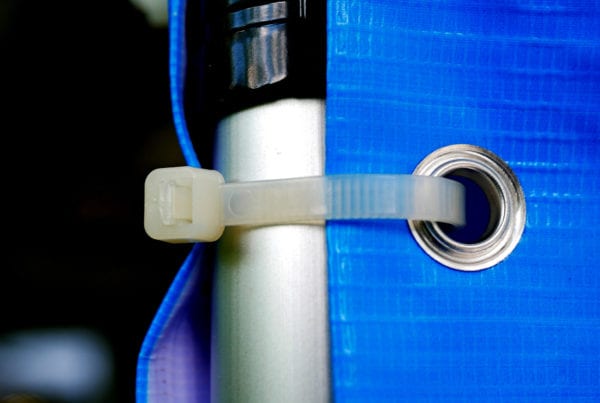

Wire ties are ties that are bare wire and have a couple of circles or loops at the end of the tie. They go through a hook in a pneumatic gun, and it gets twisted down. And there’s a lot of problems with that.

The first problem that we like to solve is the ergonomic problems of twerking down wire ties with a pneumatic gun. The second issue is that there might be some problems with oxidation to the wire tie on a product. Also, it may have potential damage to the product because it has no insulation.

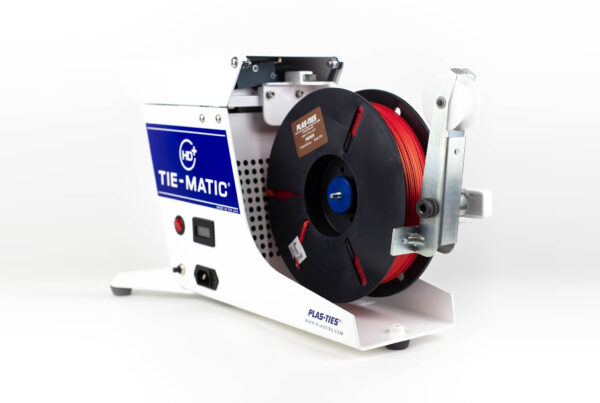

Closure of bandsaws is a specific solution that Plas-Ties created for its customers. It’s a coil of bandsaws that they were applying a wire tie and twerking it down with the pneumatic gun. Plas-Ties came with a solution that provided an efficient and quick process to tie up with a twist tie. Also, it is also a coated wire tie.

Coatings for Wire Ties

There’s a whole host of coatings for the customer. For example, a customer with bandsaws ended up speeding up their operation. They also reduced all the ergonomic pitfalls of doing the old process and packaging. This helped them speed up, which got their product out faster. They’re a very happy customer and we were happy to serve them.

Wire ties are useful in businesses where the application is more industrial. It is where the application is more robust and the demands on the tie need a higher tensile strength. Also, Plas-Ties has great solutions for these applications. XL8 is a good example. It is a tie that our customer uses in a factory where they are tying very large burlap sacks full of railroad tie nails. Also, they’re about 80 to 100 pounds per sack, and those bags need to stay closed when they move around the factory floor. Our machine does an efficient job and provides a strong closure in that application.

Wire ties are useful in businesses where the application is more industrial. It is where the application is more robust and the demands on the tie need a higher tensile strength. Also, Plas-Ties has great solutions for these applications. XL8 is a good example. It is a tie that our customer uses in a factory where they are tying very large burlap sacks full of railroad tie nails. Also, they’re about 80 to 100 pounds per sack, and those bags need to stay closed when they move around the factory floor. Our machine does an efficient job and provides a strong closure in that application.

Smart Tyer Saves Time and Effort

We also have a tie called the Smart Tyer. It is being used in Mexico, where they decided to use the Smart Tyer to close large sacks of cement. Also, it’s a very industrial operation, and they were prior, tying these sacks by hand. It revolves back to the ergonomic benefits of the wire ties. Also, this is so that factory employees do not have to tie down these tough ties by hand.

All this movement was creating a lot of stress on their bodies, it wasn’t very efficient, it was slow. Also, they used our machine to:

- Help out their employees

- Speed up the process

- Time to market

Everybody’s trying to get their product out the door. That’s what Plas-Ties does, help a product get out the door for our customers.

Other Applications

There are other applications out there if ergonomics and speed don’t matter. Also, there are applications like a bare wire that’s tied by hand onto your product and that might serve you well. This is if you want the low-cost solution. But at Plas-Ties, we focus on providing a speedy application. We also focus on the ergonomic benefit of improving the employee experience. Also, our ties close up the product and get it out the door as fast as possible. That’s what Plas-Ties does.